Share to

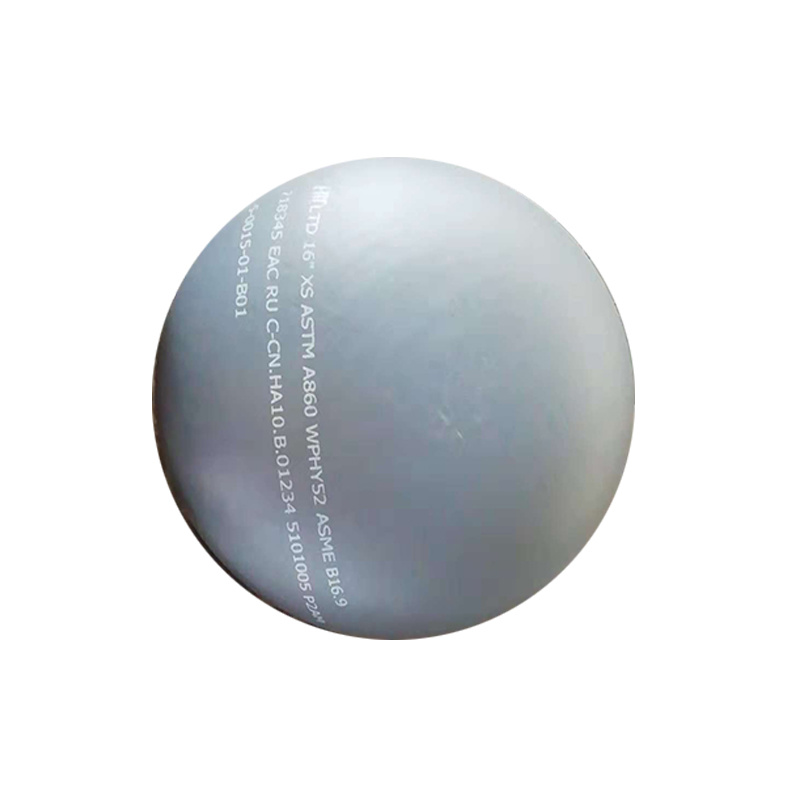

Seamless Steel Pipe

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Description

-

Definition and manufacturing process

Definition: Seamless steel pipe is a long strip of steel with a hollow cross-section and no joints around it. It is made of steel ingot or solid tube blank through perforation to make wool tube, and then hot rolled, cold rolled or cold drawn to make. Because there are no welds, seamless steel pipes perform better in high-pressure, high-strength working environments.

Manufacturing process:

Perforation process: This is the first step in the manufacture of seamless steel pipes. Taking the hot-rolled seamless steel pipe as an example, the solid tube blank is first heated to the appropriate temperature, and then perforated by the perforator. Common perforation methods are diagonal perforation and pressure perforation. Cross-rolling perforation is the use of roll rotation and axial movement, so that the tube blank gradually formed hollow tube between the roll and the head. Pressure perforation is to make the metal in the center part of the tube blank flow to the four sides through the pressure action, thus forming the capillary.

Hot rolling process: the perforated tube enters the hot rolling process. In the hot rolling process, the tube is rolled through a series of rolls so that its wall thickness and outside diameter reach the specified dimensions. Hot-rolled seamless steel pipe is characterized by relatively low dimensional accuracy, but high production efficiency, suitable for large-scale production of general purpose seamless steel pipes, such as structural steel pipes for construction, steel pipes for conveying low-pressure fluids, etc.

Cold rolling and cold drawing process: For some seamless steel pipes with high dimensional accuracy and surface quality requirements, cold rolling or cold drawing process is required. Cold rolling is the rolling of steel pipe at normal temperature, through the pressure of the roll to reduce the wall thickness of steel pipe, reduce the outside diameter, and improve the strength and surface quality of steel pipe. Cold drawing is to stretch the steel pipe through the drawing hole, which can also achieve the purpose of thinning the size and improving the quality. Cold-rolled and cold-drawn seamless steel pipes have high dimensional accuracy and good surface finish, and are often used in the manufacture of high-precision mechanical parts and high-pressure pipes.

Performance characteristics

Superior mechanical properties: Seamless steel pipe because there is no weld, the overall strength and toughness is high. When subjected to internal pressure, external pressure and axial tension and other loads, the performance of seamless steel pipes is more stable. For example, in high-pressure oil and natural gas pipeline systems, seamless steel pipes can withstand pressures of up to tens of mpa or even higher, without breaking and other safety hazards. Its yield strength and tensile strength can reach a very high level according to different materials and manufacturing processes, and can meet the strength requirements of various industrial fields.

High dimensional accuracy and surface quality: Especially the seamless steel pipe after cold rolling and cold drawing process, the dimensional accuracy of its outer diameter and wall thickness can reach a very high standard. For example, for some seamless steel pipes used in precision machinery manufacturing, the outer diameter tolerance can be controlled within ±0.05mm, and the wall thickness tolerance can be controlled within ±0.03mm. At the same time, the surface finish of the seamless steel pipe is good, there is no weld trace, which is conducive to subsequent processing and use, such as electroplating, coating and other surface treatment, to obtain a more uniform and beautiful effect.

Good corrosion resistance: the material of the seamless steel pipe itself (such as stainless steel seamless steel pipe) and its dense structure make it have good corrosion resistance. In some corrosive environments, such as acidic or alkaline medium transportation pipelines in chemical production, seamless steel pipes can be further enhanced by appropriate surface treatment (such as passivation, painting, etc.). Compared with the welded steel pipe, the seamless steel pipe has more advantages in corrosion resistance because it has no weak link of weld, reducing the risk of leakage caused by weld corrosion.

Seamless Steel Pipe

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!